The Challenge

As the economy continues to run at high speed, plant utilization remains high. Unexpected machine outages become not only inconvenient but can lead to lost sales.

All equipment wears out. The challenge is to determine where it is on its failure curve and to make repairs at the right time - before there is a catastrophic failure, but not so early in the curve that the machine is being over maintained.

The Service

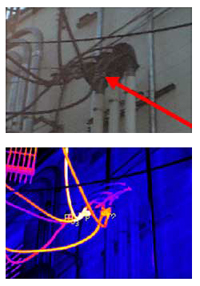

Because failing electrical equipment begins to give off heat before any other evidence of deterioration is visible, infrared inspections can find problems before they become catastrophes.

Bearings have similar characteristics, they produce heat at the beginning of the failure cycle.

We provide full inspections of your entire facility or spot inspections of suspected problem areas.

You receive a complete report of any problems found. The report gives you all the data you need to create a plan of action to deal with the maintenance needs identified.

The Benefit

-

Infrared inspections are done while the plant is running causing little or no interference with production.

-

Maintenance costs are reduced because the information from the inspections allows you to service equipment only when it needs it.

-

Because most problems are found far enough in advance of failure that you can schedule the repairs, the inspection allows you to make repairs when they will have the least affect on production.

Inductive heating on bus support.

Hot connections at Hot connections at

plant service entrance.

|

|